Chiyambi:

API 5L ndi muyezo wokhazikitsidwa ndi American Petroleum Institute (API) wa mapaipi achitsulo opanda msoko komanso olumikizidwa omwe amagwiritsidwa ntchito m'mayendedwe mkati mwa mafakitale amafuta ndi gasi. Womic Steel, wopanga mapaipi otsogola a API 5L, amapereka zinthu zambiri zomwe zimakwaniritsa magiredi ndi zofunikira zosiyanasiyana. Nkhaniyi ikupereka kufananiza mwatsatanetsatane kwa kapangidwe ka mankhwala, mawonekedwe a makina, ndi miyezo yoyesera ya magiredi osiyanasiyana a API 5L, onse a PSL1 ndi PSL2 m'mitundu itatu ya mapaipi: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), ndi SMLS (Seamless).

Mphamvu Yopanga ndi Kusiyanasiyana:

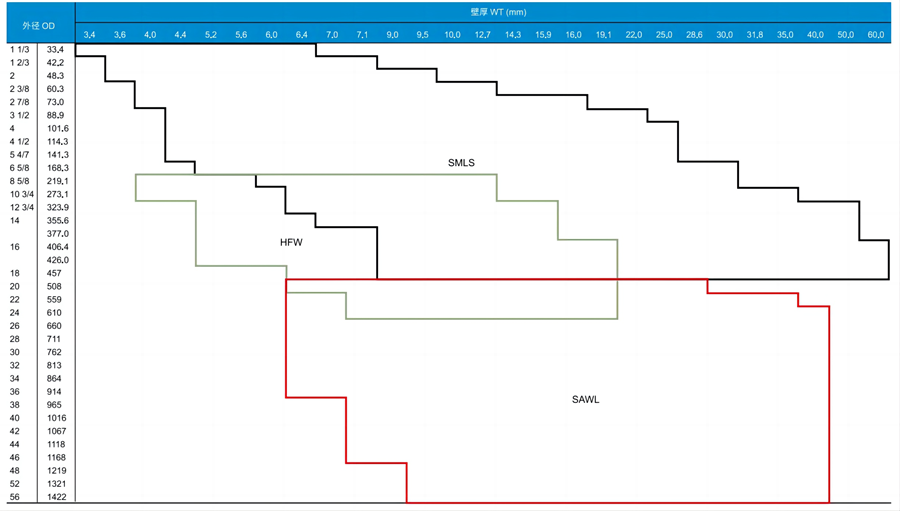

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Ochepera mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Kulekerera kwa M'mimba mwake wa Kunja

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| API SPEC SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ± 2.0mm | ± 1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Dziwani: D ndi m'mimba mwake wakunja kwa chitoliro.

Kupirira Kukhuthala kwa Khoma

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| API SPEC ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst <25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

Kusanthula kwa Mankhwala

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Pcm | 备注 |

| kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | |||||

| API SPEC 5L | 无缝管 | PSL1 | L210 kapena A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 kapena B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 kapena X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 kapena X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 kapena X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 kapena X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 kapena X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 kapena X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 kapena X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N kapena BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | CFO | ||

| L290N kapena X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N kapena X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N kapena X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N kapena X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N kapena X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Monga momwe anavomerezera | d,g,o | ||||

| L245Q kapena BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q kapena X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q kapenaX46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 kapena ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q kapena X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q kapena X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q kapena X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q kapena X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q kapena X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Monga momwe anavomerezera | h, ine | ||||

| 酸性服 | L245NS kapena BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| L290NS kapena X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS kapena X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS kapena X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS kapena BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS kapena X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS kapena X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS kapena X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS kapena X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS kapena X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS kapena X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS kapena X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Pcm | 备注 |

| kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO kapena BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,Ine,m |

| L290NO kapena X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO kapena X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, Ine, m | |||

| L360NO kapena X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, Ine | |||

| L245QO kapena BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO kapena X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO kapena X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO kapena X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO kapena X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO kapena X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO kapena X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 kapena X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO kapena X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Monga momwe anavomerezera | d,I,n | ||||

| 焊管 | PSL1 | L245 kapena B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 kapenaX42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 kapenaX46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 kapena X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 kapenaX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 kapenaX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 kapena X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 kapena X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M kapena BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M kapena X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M kapena X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M kapena X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M kapena X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M kapena X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M kapena X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M kapena X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M kapena X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Pcm | 备注 |

| kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | kuchuluka | |||||

| API SPEC 5L | 焊管 | 酸性服 | L245MS kapena BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS kapena X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS kapena X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS kapena X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS kapena X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS kapena X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS kapena X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS kapena X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO kapena BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO kapena X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO kapena X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Ine, m | |||

| L360MO kapena X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO kapena X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO kapena X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO kapena X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO kapena X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO kapena X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | PSL1 | L210 kapena A | Ochepera | 210 | 335 | a |

| 335 |

| L245 kapena B | Ochepera | 245 | 415 | a |

| 415 | ||

| L290 kapena X42 | Ochepera | 290 | 415 | a |

| 415 | ||

| L320 kapena X46 | Ochepera | 320 | 435 | a |

| 435 | ||

| L360 kapena X52 | Ochepera | 360 | 460 | a |

| 460 | ||

| L390 kapena X56 | Ochepera | 390 | 490 | a |

| 490 | ||

| L415 kapena X60 | Ochepera | 415 | 520 | a |

| 520 | ||

| L450 kapena X65 | Ochepera | 450 | 535 | a |

| 535 | ||

| L485 kapena X70 | Ochepera | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N kapena BN | Ochepera | 245 | 415 | a |

| 415 | |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290N kapena X42N | Ochepera | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320N kapena X46N | Ochepera | 320 | 435 | a |

| 435 | ||

| Max | 525 | 655 |

| 0.93 |

| |||

| L360N kapena X52N | Ochepera | 360 | 460 | a |

| 460 | ||

| Max | 530 | 760 |

| 0.93 |

| |||

| L390N kapena X56N | Ochepera | 390 | 490 | a |

| 490 | ||

| Max | 545 | 760 |

| 0.93 |

| |||

| L415N kapena X60N | Ochepera | 415 | 520 | a |

| 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450Q kapena X65Q | Ochepera | 450 | 535 | a |

| 535 | ||

| Max | 600 | 760 |

| 0.93 |

| |||

| L485Q kapena X70Q | Ochepera | 485 | 570 | a |

| 570 | ||

| Max | 635 | 760 |

| 0.93 |

| |||

| L555Q kapena X80Q | Ochepera | 555 | 625 | a |

| 625 | ||

| Max | 705 | 825 |

| 0.93 |

| |||

| L625M kapena X90M | Ochepera | 625 | 695 | a |

| 695 | ||

| Max | 775 | 915 |

| 0.95 |

| |||

| L690M kapena X100M | Ochepera | 690 | 760 | a |

| 760 | ||

| Max | 840 | 990 |

| 0.97 |

| |||

| L830M kapena X120M | Ochepera | 830 | 915 | a |

| 915 | ||

| Max | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | 酸性服 | L245NS kapena BNS | Ochepera | 245 | 415 | a |

| 415 |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290NS kapena X42NS | Ochepera | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320NS kapena X46NS | Ochepera | 320 | 435 | a |

| 435 | ||

| Max | 525 | 655 |

| 0.93 |

| |||

| L360NS kapena X52NS | Ochepera | 360 | 460 | a |

| 460 | ||

| Max | 530 | 760 |

| 0.93 |

| |||

| L390QS kapena X56QS | Ochepera | 390 | 490 | a |

| 490 | ||

| Max | 545 | 760 |

| 0.93 |

| |||

| L415QS kapena X60QS | Ochepera | 415 | 520 | a |

| 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450QS kapena X65QS | Ochepera | 450 | 535 | a |

| 535 | ||

| Max | 600 | 760 |

| 0.93 |

| |||

| L485QS kapena X70QS | Ochepera | 485 | 570 | a |

| 570 | ||

| Max | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO kapena BNO | Ochepera | 245 | 415 | a | - | 415 | |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290NO kapena X42NO | Ochepera | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320NO kapena X46NO | Ochepera | 320 | 435 | a |

| 435 | ||

| Max | 520 | 655 |

| 0.93 |

| |||

| L360NO kapena X52NO | Ochepera | 360 | 460 | a |

| 460 | ||

| Max | 525 | 760 |

| 0.93 |

| |||

| L390QO kapena X56QO | Ochepera | 390 | 490 | a |

| 490 | ||

| Max | 540 | 760 |

| 0.93 |

| |||

| L415QO kapena X60QO | Ochepera | 415 | 520 | a | - | 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450QO kapena X65QO | Ochepera | 450 | 535 | a | - | 535 | ||

| Max | 570 | 760 |

| 0.93 |

| |||

| L485Q0 kapena X70Q0 | Ochepera | 485 | 570 | a |

| 570 | ||

| Max | 605 | 760 |

| 0.93 |

| |||

| L555QO kapena X80QO | Ochepera | 555 | 625 | a |

| 625 | ||

| Max | 675 | 825 |

| 0.93 |

Zindikirani: a: Kutalika kochepa pogwiritsa ntchito equation iyi: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 kapena X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 kapena X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 kapena X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 kapena X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Zindikirani: (1) Mitengo yomwe ili patebulo ndi yoyenera chitsanzo chokwanira cha kukula konse.

(2) Mtengo womwe uli mkati mwa bulaketi ndi mtengo wocheperako, bulaketi yakunja ndi mtengo wapakati.

(3) Kutentha kwa Mayeso: 0°C.

Miyezo Yoyesera:

Mapaipi a mzere wa API 5L opangidwa ndi Womic Steel amayesedwa mwamphamvu kuti atsimikizire kuti akukwaniritsa miyezo yapamwamba kwambiri. Miyezo yoyeserayi ikuphatikizapo:

Kusanthula kwa Mankhwala:

Kapangidwe ka mankhwala ka chitsulocho kamasanthulidwa kuti zitsimikizire kuti chikukwaniritsa zofunikira za API 5L.

Kusanthula kwa mankhwala kumachitika pogwiritsa ntchito spectrometer yowerengera mwachindunji kuti adziwe molondola kapangidwe ka chitsulocho.

Kuyesa kwa Makina:

Kapangidwe ka makina monga mphamvu yotulutsa, mphamvu yokoka, ndi kutalika kwake zimayesedwa kuti zitsimikizire kuti zikukwaniritsa zofunikira zomwe zafotokozedwa.

Kuyesa kwa makina kumachitika pogwiritsa ntchito makina oyesera kukoka a matani 60 kuti ayesere mphamvu ndi kusinthasintha kwa chitsulocho.

Kuyesa kwa Madzi:

Kuyesa kwa hydrostatic kumachitika kuti muwone ngati chitolirocho chili bwino komanso kuti chikhale cholimba mokwanira malinga ndi momwe chikugwiritsidwira ntchito.

Mapaipi amadzazidwa ndi madzi ndipo amakakamizidwa, nthawi yoyesedwa komanso kuchuluka kwa kukakamizidwa komwe kumafotokozedwa ndi miyezo ya API 5L.

Kuyesa Kosawononga (NDT):

Njira za NDT monga ultrasound testing (UT) ndi magnetic particle testing (MT) zimagwiritsidwa ntchito kuzindikira zolakwika kapena kusagwirizana kulikonse mu chitoliro.

UT imagwiritsidwa ntchito kuzindikira zolakwika zamkati, pomwe MT imagwiritsidwa ntchito kuzindikira zolakwika pamwamba.

Kuyesa Zotsatira:

Kuyesa kukhudza kumachitika kuti awone kulimba kwa chitsulocho kutentha kochepa.

Mayeso a Charpy impact test amagwiritsidwa ntchito nthawi zambiri poyesa mphamvu ya impact yomwe imatengedwa ndi chitsulo.

Kuyesa Kuuma:

Kuyesa kuuma kumachitika kuti awone kuuma kwa chitsulocho, zomwe zingasonyeze mphamvu yake komanso kuyenerera kwake kugwiritsidwa ntchito pazinthu zinazake.

Mayeso a Rockwell hardness nthawi zambiri amagwiritsidwa ntchito poyesa kuuma kwa chitsulocho.

Kufufuza kwa Kapangidwe ka Zinthu Kakang'ono:

Kuwunika kapangidwe ka chitsulo kumachitika kuti muwone kapangidwe kake ka tirigu ndi mtundu wonse wa chitsulocho.

Maikusikopu yachitsulo imagwiritsidwa ntchito pofufuza kapangidwe ka chitsulocho ndikupeza zolakwika zilizonse.

Mwa kutsatira miyezo yoyesera yokhwima iyi, Womic Steel ikuwonetsetsa kuti mapaipi ake a API 5L akukwaniritsa zofunikira zapamwamba kwambiri komanso amapereka magwiridwe antchito odalirika m'mafakitale osiyanasiyana.

Njira Yopangira:

1. Mapaipi a Chitsulo Chopanda Msoko:

- Kusankha Zinthu Zopangira: Ma billet achitsulo chozungulira chapamwamba kwambiri amasankhidwa kuti apange mapaipi achitsulo chopanda msoko.

- Kutentha ndi Kuboola: Ma billets amatenthedwa kutentha kwambiri kenako amabooledwa kuti apange chipolopolo chopanda kanthu.

- Kuzungulira ndi Kukula: Chipolopolo chobooledwacho chimapindidwa ndikutambasulidwa kufika pa mulifupi ndi makulidwe omwe mukufuna.

- Kukonza Kutentha: Mapaipi amatenthedwa ndi njira zotenthetsera monga kuphimba kapena kuyeretsa kuti awonjezere mphamvu zawo zamagetsi.

- Kumaliza: Mapaipi amadutsa munjira zomaliza monga kuwongola, kudula, ndi kuyang'aniridwa.

- Kuyesa: Mapaipi amayesedwa mosiyanasiyana, kuphatikizapo kuyezetsa kwa hydrostatic, kuyezetsa kwa ultrasound, ndi kuyezetsa kwa eddy current, kuti atsimikizire kuti ali ndi khalidwe labwino.

- Kukonza Pamwamba: Mapaipi amatha kuphimbidwa kapena kupakidwa mankhwala kuti apewe dzimbiri ndikuwonjezera mawonekedwe awo.

- Kulongedza ndi Kutumiza: Mapaipi amapakidwa mosamala ndikutumizidwa kwa makasitomala.

2. Mapaipi achitsulo a LSAW (Longitudinal Submerged Arc Welding):

- Kukonzekera Mbale: Mbale zachitsulo zapamwamba kwambiri zimakonzedwa kuti zigwiritsidwe ntchito popanga mapaipi a LSAW.

- Kupanga: Ma plate amapangidwa kukhala mawonekedwe a "U" pogwiritsa ntchito makina opindika kale.

- Kuwotcherera: Ma plate ooneka ngati "U" amawotcherera pamodzi pogwiritsa ntchito njira yowotcherera ya arc yomwe imayikidwa pansi pa nthaka.

- Kukulitsa: Msoko wolumikizidwa umakulitsidwa mpaka kukula komwe mukufuna pogwiritsa ntchito makina okulitsa mkati kapena kunja.

- Kuyang'anira: Mapaipi amayesedwa kuti awone ngati pali zolakwika komanso kulondola kwa miyeso.

- Kuyesa kwa Ultrasound: Mapaipi amayesedwa ndi ultrasound kuti azindikire zolakwika zilizonse zamkati.

- Kupindika: Malekezero a chitoliro amapindika kuti agwiritsidwe ntchito kuwotcherera.

- Kupaka ndi Kulemba: Mapaipi amatha kuphimbidwa ndi kulembedwa malinga ndi zosowa za makasitomala.

- Kulongedza ndi Kutumiza: Mapaipi amapakidwa ndi kutumizidwa kwa makasitomala.

3. Mapaipi achitsulo a HFW (High-frequency Welding):

- Kukonzekera Koyilo: Makoyilo achitsulo amakonzedwa kuti apange mapaipi a HFW.

- Kupanga ndi Kuwotcherera: Ma coil amapangidwa kukhala mawonekedwe a cylindrical kenako amawotcherera pogwiritsa ntchito kuwotcherera kwapamwamba kwambiri.

- Kutenthetsa Msoko Wothira: Msoko wothira umatenthedwa kufika kutentha kwa wothira pogwiritsa ntchito kutentha kwa induction komwe kumachitika pafupipafupi.

- Kukula: Chitoliro cholumikizidwa chimakhala ndi kukula koyenera m'mimba mwake ndi makulidwe.

- Kudula ndi Kupindika: Chitolirocho chimadulidwa kutalika komwe mukufuna ndipo malekezero ake amapindika kuti chiwongoleredwe.

- Kuyang'anira: Mapaipi amayesedwa kuti awone ngati pali zolakwika komanso kulondola kwa miyeso.

- Kuyesa kwa Madzi Osasunthika: Mapaipi amayesedwa mphamvu ndi kutuluka kwa madzi pogwiritsa ntchito kuyesa kwa madzi osasunthika.

- Kupaka ndi Kulemba: Mapaipi amapakidwa ndi kulembedwa malinga ndi zosowa za makasitomala.

- Kulongedza ndi Kutumiza: Mapaipi amapakidwa ndi kutumizidwa kwa makasitomala.

Njira zopangira mwatsatanetsatanezi zimatsimikizira kuti mapaipi achitsulo opanda msoko, LSAW, ndi HFW opangidwa ndi Womic Steel ndi apamwamba komanso odalirika, zomwe zimakwaniritsa zofunikira za mafakitale osiyanasiyana.

Chithandizo cha pamwamba:

Kukonza pamwamba pa chitsulo cha mapaipi ndikofunikira kwambiri kuti chikhale cholimba komanso kuti chikhale ndi nthawi yayitali yogwirira ntchito. Womic Steel imagwiritsa ntchito njira zosiyanasiyana zokonzera pamwamba kutengera zosowa zosiyanasiyana za makasitomala, kuphatikizapo:

1. Kuthira Magesi Otentha: Chitoliro chachitsulo chimamizidwa mu zinc yosungunuka kuti chipange gawo loteteza zinc-iron alloy, zomwe zimapangitsa kuti chisagwe ndi dzimbiri. Kuthira Magesi Otentha ndi koyenera pa mapaipi achizolowezi komanso otsika mphamvu.

2. Zophimba Zoletsa Kutupa: Zophimba zodziwika bwino zoletsa kutupa zimaphatikizapo zophimba za epoxy, zophimba za polyethylene, ndi zophimba za polyurethane. Zophimba izi zimateteza bwino ku kukhuthala ndi dzimbiri pamwamba pa chitoliro chachitsulo, ndikuwonjezera nthawi yake yogwira ntchito.

3. Kuphulitsa Mchenga: Kuphulitsa kothamanga kwambiri kumagwiritsidwa ntchito kuyeretsa chitoliro chachitsulo, kuchotsa dzimbiri ndi zinyalala pamwamba, zomwe zimapangitsa kuti pakhale maziko abwino a zophikira pambuyo pake.

4. Kupaka: Pamwamba pa chitoliro chachitsulo pakhoza kuphimbidwa ndi utoto woletsa kuwononga, utoto wa phula, ndi zina zophimba kuti ziwonjezere kukana kwake dzimbiri, zoyenera mapaipi apansi panthaka ndi mapaipi m'malo a m'nyanja.

Njira zochizira pamwambazi zimateteza bwino chitsulo cha mapaipi ku dzimbiri ndi kuwonongeka, ndikuonetsetsa kuti chikhale chodalirika komanso cholimba m'malo osiyanasiyana ovuta.

Kulongedza ndi Kuyendera:

Womic Steel imatsimikizira kuti zitsulo za mapaipi zimasungidwa bwino komanso kuti zitsulozo zimanyamulidwa bwino, ndipo imapereka njira zosinthika kuti zikwaniritse zosowa zosiyanasiyana za makasitomala:

1. Katundu Wochuluka: Pa maoda akuluakulu, zitsulo zapaipi zimatha kutumizidwa mochuluka pogwiritsa ntchito zonyamulira zapadera. Chitsulocho chimayikidwa mwachindunji m'chombocho popanda kulongedza, choyenera kunyamula katundu wambiri pamtengo wotsika.

2. LCL (Katundu Wochepera Chidebe): Pa maoda ang'onoang'ono, chitsulo cha mapaipi chingatumizidwe ngati katundu wa LCL, komwe maoda ang'onoang'ono angapo amaphatikizidwa kukhala chidebe chimodzi. Njirayi ndi yotsika mtengo pamitengo yochepa ndipo imapereka nthawi yotumizira yosinthasintha.

3. FCL (Katundu Wonse wa Chidebe): Makasitomala amatha kusankha kutumiza kwa FCL, komwe chidebe chonse chimaperekedwa ku oda yawo. Njirayi imapereka nthawi yofulumira yoyendera komanso imachepetsa chiopsezo cha kuwonongeka panthawi yogwira ntchito.

4. Kunyamula katundu wa pandege: Pa maoda ofulumira, katundu wa pandege amapezeka kuti atumizidwe mwachangu. Ngakhale kuti ndi okwera mtengo kuposa katundu wapanyanja, katundu wa pandege amapereka mayendedwe achangu komanso odalirika kuti akatumizidwe nthawi ndi nthawi.

Womic Steel imaonetsetsa kuti katundu yense wotumizidwayo wasungidwa bwino kuti asawonongeke panthawi yotumizidwa. Chitsulocho nthawi zambiri chimakulungidwa mu zipangizo zoteteza ndikuchimangirira m'mabotolo kapena pamapaleti kuti chikhale chokhazikika panthawi yotumizidwa. Kuphatikiza apo, kampaniyo imagwira ntchito limodzi ndi mabungwe odalirika otumizira katundu kuti atsimikizire kuti katunduyo watumizidwa nthawi yake komanso kuti zinthu ziyende bwino.

Zochitika Zogwiritsira Ntchito:

Mapaipi a mzere wa API 5L opangidwa ndi Womic Steel amagwiritsidwa ntchito kwambiri m'mafakitale a mafuta ndi gasi lachilengedwe ponyamula mafuta, gasi, ndi madzi ena. Amagwiritsidwanso ntchito m'mafakitale ena osiyanasiyana monga kukonza mankhwala, kupanga magetsi, ndi zomangamanga.

Mapeto:

Womic Steel ndi kampani yodalirika yopanga mapaipi a API 5L, yomwe imapereka zinthu zapamwamba kwambiri zomwe zimakwaniritsa zofunikira kwambiri za mafakitale a mafuta ndi gasi. Poganizira kwambiri za ubwino, kudalirika, komanso kukhutitsa makasitomala, Womic Steel ikupitilira kukhala chisankho chomwe makasitomala padziko lonse lapansi amakonda.

Nthawi yotumizira: Marichi-22-2024