ASTM A182 Ma Flanges Opangidwa Kapena Ozunguliridwa a Alloy-Steel, Zopangira Zopangidwa, ndi Ma Valves

ASTM A182 ndi mfundo yofunika kwambiri ya ma flange achitsulo chopangidwa kapena chokulungidwa, zolumikizira zopangidwa, ndi ma valve omwe amapangidwira kugwiritsidwa ntchito m'malo otentha kwambiri komanso opanikizika kwambiri. Muyezo uwu umapereka malangizo a kapangidwe ka mankhwala, mawonekedwe a makina, njira zoyesera, ndi zinthu zina zofunika zomwe zimatsimikizira kulimba ndi kudalirika kwa zigawozi pakugwiritsa ntchito kofunikira.

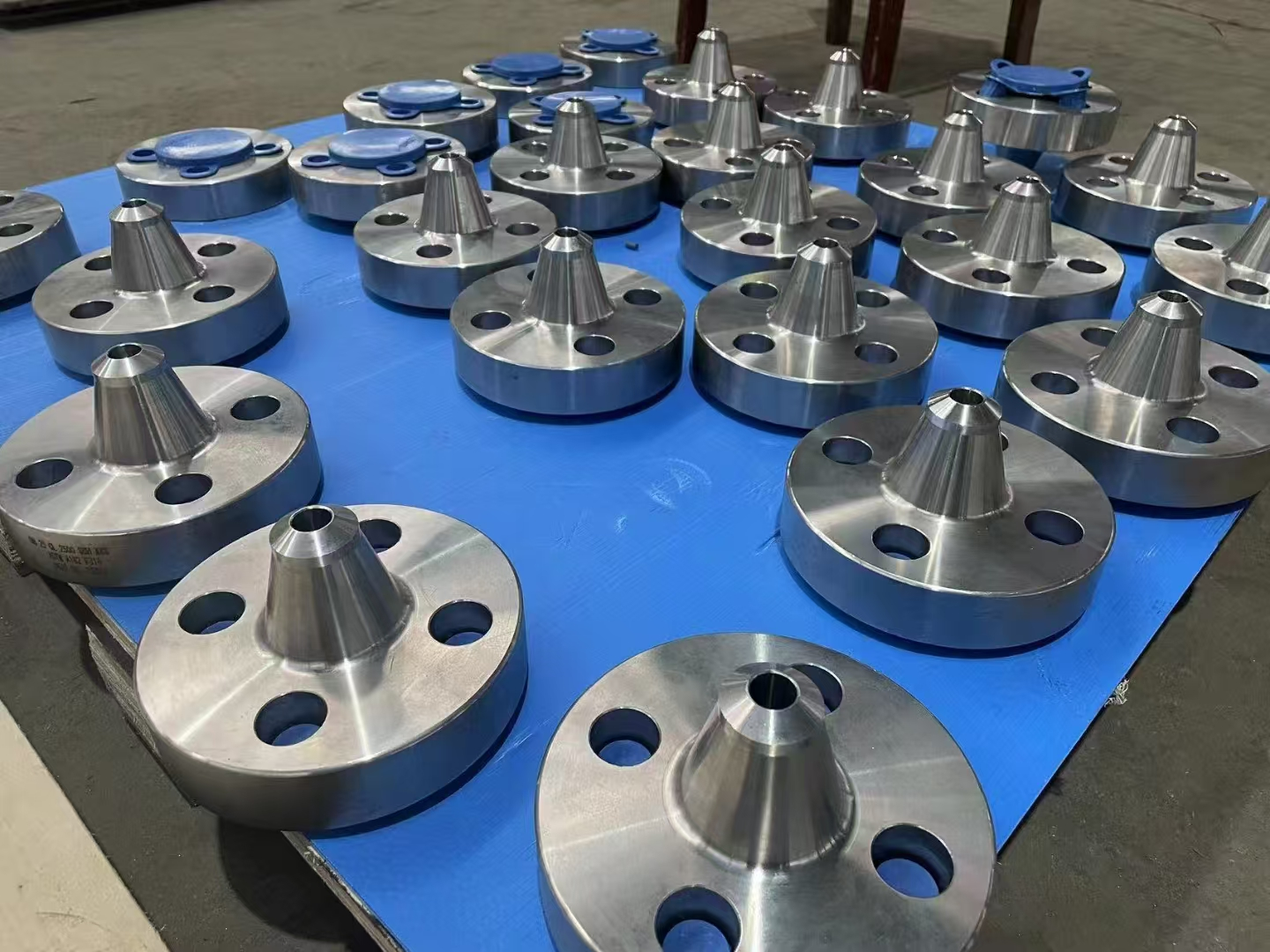

Ku Womic Steel, timapanga zinthu zosiyanasiyana zomwe zimatsatira muyezo wa ASTM A182, zomwe zimapereka khalidwe lapamwamba komanso kulondola. M'nkhaniyi, tifufuza zinthu zofunika kwambiri pa muyezo uwu ndikuwonetsa luso la Womic Steel popanga zinthu komanso ubwino wosankha ife ngati ogulitsa anu.

Mitundu ya Zogulitsa Zophimbidwa ndi ASTM A182

ASTM A182 imaphimba zinthu zosiyanasiyana zachitsulo zopangidwa kapena zokulungidwa, kuphatikizapo:

1. Ma Flange - Izi zimagwiritsidwa ntchito kulumikiza mapaipi, ma valve, mapampu, ndi zida zina mu dongosolo la mapaipi.

2. Zopangira Zopangira - Izi zikuphatikizapo zigongono, ma tee, zochepetsera, zipewa, ndi ma unions omwe amagwiritsidwa ntchito m'makina amphamvu kwambiri.

3. Ma valve - Opangidwa kuti azilamulira kuyenda kwa madzi m'malo otentha kwambiri.

4. Zinthu Zina Zopangidwa Kapena Zopindidwa – Izi zikuphatikizapo ma valve ndi zolumikizira zomwe zimagwiritsidwa ntchito mu nthunzi, gasi, ndi machitidwe ena amphamvu kwambiri.

Ku Womic Steel, timapanga zinthuzi mu kukula, zipangizo, ndi mawonekedwe osiyanasiyana, kuonetsetsa kuti zikukwaniritsa zosowa zanu.

Zipangizo ndi Kuphatikizika kwa Mankhwala

Muyezo wa ASTM A182 umatchula mitundu ingapo ya zinthu, kuphatikizapo chitsulo cha kaboni, chitsulo chopanda aloyi wambiri, ndi chitsulo chosapanga dzimbiri, chilichonse chili ndi zofunikira zosiyanasiyana pakupanga mankhwala. Nazi zina mwa zinthu zofunika kwambiri zomwe zili mu ASTM A182:

1. Giredi F1 - Chitsulo cha kaboni chokhala ndi kapangidwe kake komwe kamachilola kugwira ntchito kutentha pang'ono.

2. Giredi F5, F9, F11, F22 - Zitsulo zochepa zopangidwa kuti zipirire kutentha ndi kupsinjika kwakukulu.

3. Giredi F304, F304L, F316, F316L – Zitsulo zosapanga dzimbiri za Austenitic, zomwe zimagwiritsidwa ntchito kwambiri chifukwa cha kukana dzimbiri m'malo osiyanasiyana opangira mankhwala.

Pa mtundu uliwonse, kapangidwe ka mankhwala kamayendetsedwa mosamala kuti akwaniritse zofunikira za ASTM. Pansipa pali tsatanetsatane wa kapangidwe ka mankhwala ndi mawonekedwe a makina a chinthu chilichonse.

Kapangidwe ka Mankhwala ndi Katundu wa Makina

1. Giredi F1 - Chitsulo cha Kaboni

Kapangidwe ka Mankhwala:

Kaboni (C): 0.30-0.60%

Manganese (Mn): 0.60-0.90%

Silikoni (Si): 0.10-0.35%

Sulfure (S): ≤ 0.05%

Phosphorus (P): ≤ 0.035%

Katundu wa Makina:

Mphamvu Yokoka (MPa): ≥ 485

Mphamvu Yotulutsa (MPa): ≥ 205

Kutalika (%): ≥ 20

2. Giredi F5 - Chitsulo Chochepa cha Aloyi

Kapangidwe ka Mankhwala:

Kaboni (C): 0.10-0.15%

Manganese (Mn): 0.50-0.80%

Chromium (Cr): 4.50-5.50%

Molybdenum (Mo): 0.90-1.10%

Sulfure (S): ≤ 0.03%

Phosphorus (P): ≤ 0.03%

Katundu wa Makina:

Mphamvu Yokoka (MPa): ≥ 655

Mphamvu Yotulutsa (MPa): ≥ 345

Kutalika (%): ≥ 20

3. Giredi F304 - Chitsulo Chosapanga Dziwe cha Austenitic

Kapangidwe ka Mankhwala:

Kaboni (C): ≤ 0.08%

Manganese (Mn): 2.00-2.50%

Chromium (Cr): 18.00-20.00%

Nikeli (Ni): 8.00-10.50%

Sulfure (S): ≤ 0.03%

Phosphorus (P): ≤ 0.045%

Katundu wa Makina:

Mphamvu Yokoka (MPa): ≥ 515

Mphamvu Yotulutsa (MPa): ≥ 205

Kutalika (%): ≥ 40

4. Giredi F316 - Chitsulo Chosapanga Dzimbiri cha Austenitic (Chosagonjetsedwa ndi Dzimbiri)

Kapangidwe ka Mankhwala:

Kaboni (C): ≤ 0.08%

Manganese (Mn): 2.00-3.00%

Chromium (Cr): 16.00-18.00%

Nikeli (Ni): 10.00-14.00%

Molybdenum (Mo): 2.00-3.00%

Sulfure (S): ≤ 0.03%

Phosphorus (P): ≤ 0.045%

Katundu wa Makina:

Mphamvu Yokoka (MPa): ≥ 515

Mphamvu Yotulutsa (MPa): ≥ 205

Kutalika (%): ≥ 40

Katundu wa Makina ndi Zofunikira pa Impact

Makhalidwe a makina monga mphamvu yokoka, mphamvu yotulutsa, ndi kutalika ndizofunikira kwambiri kuti zitsimikizire kuti zigawo zopangidwazo zimagwira ntchito bwino pansi pa kupanikizika. ASTM A182 imatchula makhalidwe awa pa mtundu uliwonse wa zinthu, ndipo zofunikira zimasiyana malinga ndi momwe zimagwiritsidwira ntchito.

Kuyesa zotsatirandi gawo lina lofunika kwambiri la muyezo, kuonetsetsa kuti ziwalo zopangidwa zimatha kupirira kusintha kwadzidzidzi kwa kutentha kapena kugwedezeka. Mwachitsanzo, muyezo ungafunike mayeso a Charpy V-notch kuti atsimikizire kulimba munyengo zotentha zochepa.

Njira Zopangira ndi Zofunikira pa Kutentha

Womic Steel imatsatira njira zokhwima zopangira kuti zitsimikizire kuti zinthu zonse za ASTM A182 zikukwaniritsa miyezo yapamwamba kwambiri. Izi zikuphatikizapo:

Kupanga ndi Kuzungulira – Makina athu apamwamba kwambiri amatsimikizira kuti gawo lililonse limapangidwa kapena kuzunguliridwa molingana ndi kukula ndi kulekerera kolondola.

Kutentha Chithandizo – Kuchiza kutentha n'kofunika kwambiri kuti pakhale mphamvu zomwe makina amafunikira. ASTM A182 imafuna njira zinazake zochizira kutentha kutengera mtundu wa zinthu, monga kuphimba, kuzimitsa, ndi kutenthetsa kuti zikhale zolimba komanso zolimba.

kuwotcherera - Timapereka njira zowotcherera zomwe zapangidwa mwapadera pazinthu za ASTM A182, kuonetsetsa kuti kulumikizana kodalirika komanso kosataya madzi. Njira zowotcherera zimayendetsedwa mosamala kuti zitsimikizire kuti zida zowotcherera zikukwaniritsa kapena kupitirira mphamvu ya zinthu zoyambira.

Kuyendera ndi Kuyesa

Timachita zinthu zonsekuyang'anira ndi kuyesakutsimikizira kuti zinthu zonse zikukwaniritsa muyezo wa ASTM A182. Izi zikuphatikizapo:

Kuyang'ana Zooneka - Pa zolakwika kapena zolakwika pamwamba.

Kuyesa Kosawononga (NDT) - Kuphatikizapo kuyesa kwa ultrasound ndi kuyang'anira x-ray kuti mupeze zolakwika zamkati.

Kuyesa kwa Makina - Mphamvu yokoka, mphamvu yotulutsa, ndi kuyesa mphamvu kuti zitsimikizire momwe zinthuzo zikuyendera pamene zinthuzo zikupanikizika.

Kusanthula kwa Mankhwala - Kuonetsetsa kuti kapangidwe ka mankhwala kakutsatira zomwe zili mu muyezo.

Zogulitsa zathu zonse zimatsatira njira zowongolera khalidwe, ndipo timapereka satifiketi yotsatizana yotsatizana ndi oda iliyonse.

Mafotokozedwe a Zamalonda ndi Kukula kwa Makulidwe

At Chitsulo cha Womic, timapereka mitundu yosiyanasiyana ya zinthu za ASTM A182 mu kukula ndi mawonekedwe osiyanasiyana.kukula kwakezikuphatikizapo:

Ma Flange: Kuyambira 1/2" mpaka 60" m'mimba mwake.

Zopangira Zopangira: Kuyambira 1/2" mpaka 48" m'mimba mwake.

Mavavu: Masayizi opangidwa mwamakonda kuti agwirizane ndi zofunikira za dongosolo lanu.

Zogulitsa zathu zimapezeka m'magawo osiyanasiyana a kupanikizika ndi zipangizo, zomwe zimatsimikizira kuti tikhoza kukwaniritsa zosowa za polojekiti yanu.

Ubwino wa Kupaka, Kutumiza, ndi Kuyendera

Timamvetsetsa kufunika kotumiza katundu nthawi yake komanso motetezeka. Womic Steel imaperekama CD osinthidwazomwe zimateteza umphumphu wa zinthu panthawi yoyendera. Kaya ndi kudzera mu kutumiza zinthu m'makontena kapena njira zapadera zotumizira katundu, timaonetsetsa kuti oda yanu ifika pa nthawi yake komanso ili bwino.

Zathuukatswiri wa mayendedwendipo mgwirizano mwachindunji ndi makampani otumiza katundu umatipatsa mwayi wopereka mitengo yopikisana komanso njira zotumizira katundu mosavuta.

Kusintha ndi Ntchito Zowonjezera

Kuwonjezera pa mitundu yathu yambiri ya zinthu zokhazikika, Womic Steel imaperekakupanga mwamakondapa zofunikira zapadera. Tikhoza kusintha miyeso, zipangizo, ndi mapeto kuti zigwirizane ndi ntchito yanu yeniyeni.

Ntchito Zokonzakuphatikizapo:

Kukonza Machining - Kuti musinthe zinthu molondola kuti zigwirizane ndi zosowa zanu.

kuwotcherera - Zolumikizira kapena zolumikizira za flange zomwe zakonzedwa mwamakonda.

Zophimba ndi Ntchito Zoletsa Kudzikundikira - Kupereka chitetezo chokhalitsa kutengera zomwe mukufuna pa chilengedwe.

N'chifukwa Chiyani Muyenera Kusankha Chitsulo cha Womic?

Kutha Kupanga: Tili ndi malo opangira zinthu zamakono komanso otha kutulutsa zinthu zambiri.

Ukatswiri waukadauloGulu lathu lili ndi mainjiniya ndi akatswiri aluso kwambiri odzipereka kupanga zinthu zapamwamba kwambiri.

Ubwino wa Unyolo Wopereka: Tili ndi ubale wolimba ndi ogulitsa zinthu zopangira, zomwe zimatsimikizira kuti zinthuzo zatumizidwa nthawi yake komanso kuti mtengo wake ndi wabwino.

Zosankha Zosintha: Timapereka njira zothetsera mavuto kuti zikwaniritse zofunikira za polojekitiyi, kuphatikizapo kuwotcherera, kukonza makina, ndi kupaka utoto.

Mapeto

TheMuyezo wa ASTM A182imaonetsetsa kuti zinthu zopangidwa ndi chitsulo chopangidwa ndi chokulungidwa ndi chokulungidwa zikugwira ntchito bwino komanso modalirika. Womic Steel ndi mnzanu wodalirika wa zinthu zapamwamba zopangidwa motsatira muyezo uwu, zomwe zimapereka chithandizo chokwanira kuyambira pazinthu zaukadaulo mpaka zinthu zoyendera. Kaya mukufuna kukula koyenera, kuwotcherera, kapena zokutira zapadera, timapereka mayankho okonzedwa kuti akwaniritse zosowa zanu, ndikuwonetsetsa kuti ntchito yabwino kwambiri komanso kudalirika kotumizira.

Webusaiti: www.womicsteel.com

Imelo: sales@womicsteel.com

Foni/WhatsApp/WeChat: Victor: +86-15575100681 kapena Jack: +86-18390957568

Nthawi yotumizira: Epulo-21-2025