Kodi flange ndi chiyani?

Flange mwachidule, mawu wamba, nthawi zambiri amatanthauza thupi lachitsulo lofanana ndi disk kuti litsegule mabowo angapo okhazikika, lomwe limagwiritsidwa ntchito kulumikiza zinthu zina, chinthu chamtunduwu chimagwiritsidwa ntchito kwambiri mumakina, kotero chimawoneka chachilendo pang'ono, bola ngati chimadziwika kuti flange, dzina lake limachokera ku flange yaku England. Kuti chitoliro ndi kulumikizana kwa chitoliro cha ziwalo, zolumikizidwa kumapeto kwa chitoliro, flange ili ndi malo otseguka, zomangira zopangira ma flange awiri. Yolumikizidwa mwamphamvu, pakati pa flange ndi chisindikizo cha gasket.

Flange ndi ziwalo zooneka ngati diski, zomwe zimapezeka kwambiri muukadaulo wa mapaipi, flange imagwiritsidwa ntchito pawiri.

Ponena za mitundu yolumikizira ma flange, pali zinthu zitatu:

- Ma flange a mapaipi

- Gasket

- Kulumikizana kwa bolt

Nthawi zambiri, pamakhala gasket ndi bolt yapadera yomwe imapangidwa kuchokera ku chinthu chomwecho monga gawo la flange ya chitoliro. Flanges yodziwika kwambiri ndi flanges zachitsulo chosapanga dzimbiri. Flanges, kumbali ina, imapezeka muzipangizo zosiyanasiyana kuti igwirizane ndi zofunikira za malo. Zina mwazipangizo zodziwika bwino za flange ndi monel, inconel, ndi chrome molybdenum, kutengera zomwe zimafunika pamalo enieni. Kusankha bwino kwazipangizo kuyenera kutengera mtundu wa makina omwe mukufuna kugwiritsa ntchito flange yokhala ndi zofunikira zinazake.

Mitundu 7 Yodziwika ya Flanges

Pali mitundu yosiyanasiyana ya ma flange omwe angasankhidwe malinga ndi zofunikira za malowo. Kuti agwirizane ndi kapangidwe ka flange yoyenera, ntchito yodalirika komanso moyo wautali wautumiki ziyenera kutsimikizika ndipo mtengo woyenera kwambiri uyenera kuganiziridwa.

1. flange yolumikizidwa:

Ma flange okhala ndi ulusi, omwe ali ndi ulusi m'bowo la flange, amaikidwa ulusi wakunja pa cholumikizira. Kulumikiza kwa ulusi pano cholinga chake ndi kupewa kuwotcherera nthawi zonse. Kumalumikizidwa makamaka ndi ulusi wofanana ndi chitoliro chomwe chikuyenera kuyikidwa.

2. Ma flange a socket weld

Mtundu uwu wa flange nthawi zambiri umagwiritsidwa ntchito pa mapaipi ang'onoang'ono komwe kukula kwa kutentha kochepa komanso dera lopanikizika pang'ono kumadziwika ndi kulumikizana komwe payipi imayikidwa mkati mwa flange kuti zitsimikizire kulumikizana ndi weld imodzi kapena yambiri. Izi zimapewa zoletsa zokhudzana ndi malekezero a ulusi poyerekeza ndi mitundu ina ya flange yolumikizidwa, motero zimapangitsa kuti kukhazikitsa kukhale kosavuta.

3. Ma flange ozungulira

Flange yozungulira ndi mtundu wa flange yomwe imafuna kuti mbali ya stub ilumikizidwe ndi cholumikizira kuti igwiritsidwe ntchito ndi flange yothandizira kuti ipange kulumikizana kwa flange. Kapangidwe kameneka kapangitsa njira iyi kukhala yotchuka m'njira zosiyanasiyana komwe malo enieni ndi ochepa, kapena komwe kumafunika kuchotsedwa pafupipafupi, kapena komwe kumafunika kukonza kwakukulu.

4. Ma flange otsetsereka

Ma flange otsetsereka ndi ofala kwambiri ndipo amapezeka m'mitundu yosiyanasiyana kuti agwirizane ndi makina okhala ndi kuthamanga kwa madzi ambiri komanso ma throughputs ambiri. Kungogwirizanitsa flange ndi m'mimba mwake wakunja kwa chitoliro kumapangitsa kuti kulumikizanako kukhale kosavuta kwambiri. Kukhazikitsa ma flange awa ndiukadaulo pang'ono chifukwa kumafuna kuwotcherera fillet mbali zonse ziwiri kuti flange igwirizane ndi chitolirocho.

5. Ma flange akhungu

Mitundu iyi ya ma flange ndi yoyenera kwambiri pothetsa mapaipi. Mbale yobisika imapangidwa ngati diski yopanda kanthu yomwe imatha kumangidwa ndi bolt. Izi zikayikidwa bwino ndikugwirizanitsidwa ndi gasket yoyenera, zimathandiza kuti pakhale kutseka kwabwino ndipo zimakhala zosavuta kuchotsa zikafunika.

6. Ma Flanges a Khosi Osenda

Ma flange a khosi lopindika ndi ofanana kwambiri ndi ma flange a lap, koma amafunika kuwotcherera matako kuti ayike. Ndipo kulimba kwa magwiridwe antchito a dongosololi komanso kuthekera kwake kupindika kambirimbiri ndikugwiritsidwa ntchito mu makina opanikizika kwambiri komanso kutentha kwambiri zimapangitsa kuti ikhale chisankho chachikulu cha mapaipi opangira zinthu.

7. Ma flange apadera

Mtundu uwu wa flange ndi wodziwika bwino kwambiri. Komabe, pali mitundu yambiri ya flange yapadera yomwe ikupezeka kuti igwirizane ndi ntchito zosiyanasiyana komanso malo osiyanasiyana. Pali njira zina zosiyanasiyana monga nipo flanges, weldo flanges, expansion flanges, orifices, long weld necks ndi reducer flanges.

Mitundu 5 Yapadera ya Flanges

1. WeldoFlange

Flange ya Weldo ndi yofanana kwambiri ndi flange ya Nipo chifukwa ndi kuphatikiza kwa ma flange olumikizira matako ndi maulumikizidwe a nthambi. Ma flange a Weldo amapangidwa kuchokera ku chitsulo chimodzi cholimba, m'malo momangirira ziwalo payokha pamodzi.

2. Flange ya Nipo

Nipoflange ndi chitoliro cha nthambi chopendekeka pa ngodya ya madigiri 90, ndi chinthu chopangidwa pophatikiza ma flange olumikizira matako ndi Nipolet yopangidwa. Ngakhale kuti Nipo flange imapezeka kuti ndi chidutswa chimodzi cholimba cha chitsulo chopangidwa, sizikumveka kuti ndi zinthu ziwiri zosiyana zolumikizidwa pamodzi. Kukhazikitsa kwa Nipoflange kumaphatikizapo kuwotcherera ku gawo la Nipolet la zida kuti liyendetse chitoliro ndikuyika gawo la flange ku flange ya stub payipi ndi ogwira ntchito pa mapaipi.

Ndikofunikira kudziwa kuti ma Nipo flanges amapezeka mu mitundu yosiyanasiyana ya zinthu monga kaboni, zitsulo za kaboni zotentha kwambiri komanso zotsika, zitsulo zosapanga dzimbiri, ndi nickel alloys. Ma Nipo flanges nthawi zambiri amapangidwa ndi zinthu zolimbikitsidwa, zomwe zimathandiza kuwapatsa mphamvu yowonjezera poyerekeza ndi Nipo flange wamba.

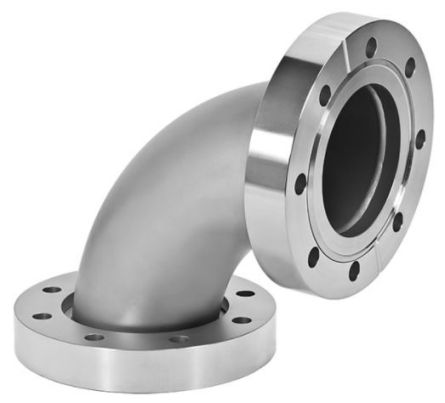

3. Elboflange ndi Latroflange

Elboflange imadziwika kuti ndi kuphatikiza kwa flange ndi Elbolet pomwe Latroflange imadziwikanso kuti kuphatikiza kwa flange ndi Latrolet. Ma flange a chigongono amagwiritsidwa ntchito ku mapaipi a nthambi pa ngodya ya madigiri 45.

4. Ma flange ozungulira

Kugwiritsa ntchito ma flange ozungulira kumathandiza kuti mabowo a bolt agwirizane pakati pa ma flange awiri ogwirizana, zomwe zimathandiza kwambiri nthawi zambiri, monga kuyika mapaipi akuluakulu, mapaipi a pansi pamadzi kapena a m'mphepete mwa nyanja ndi malo ena ofanana. Mitundu iyi ya ma flange ndi yoyenera kugwiritsa ntchito madzi ofunikira mu mafuta, gasi, ma hydrocarbon, madzi, mankhwala ndi zina zomwe zimagwiritsidwa ntchito poyang'anira petrochemical ndi madzi.

Pa mapaipi akuluakulu, chitolirocho chimakhala ndi flange yokhazikika yolumikizira mbali imodzi ndi flange yozungulira mbali inayo. Izi zimagwira ntchito pongozungulira flange yozungulira pa payipi kuti woyendetsa akwaniritse bwino mabowo a bolt m'njira yosavuta komanso yachangu.

Zina mwa miyezo yayikulu ya ma flange a mphete zozungulira ndi ASME kapena ANSI, DIN, BS, EN, ISO, ndi zina. Chimodzi mwa miyezo yotchuka kwambiri yogwiritsira ntchito petrochemical ndi ANSI kapena ASME B16.5 kapena ASME B16.47. Ma flange ozungulira ndi ma flange omwe angagwiritsidwe ntchito mu mawonekedwe onse ofanana a flange. Mwachitsanzo, ma weld necks, slip ons, lap joints, socket welds, ndi zina zotero, m'magulu onse azinthu, m'makulidwe osiyanasiyana kuyambira 3/8" mpaka 60", ndi kupsinjika kuyambira 150 mpaka 2500. Ma flange awa amatha kupangidwa mosavuta kuchokera ku kaboni, alloy, ndi zitsulo zosapanga dzimbiri.

5. Ma flange okulitsa

Ma flange owonjezera amagwiritsidwa ntchito kuwonjezera kukula kwa chitoliro kuchokera pamalo ena kupita kwina kuti alumikize chitolirocho ku zida zina zamakina monga mapampu, ma compressor, ndi ma valve omwe amapezeka kuti ali ndi kukula kosiyana kwa malo olowera.

Ma flange owonjezera nthawi zambiri amakhala ma flange olumikizidwa ndi matako omwe ali ndi dzenje lalikulu kwambiri kumapeto osapindika. Angagwiritsidwe ntchito kuwonjezera kukula kamodzi kapena kawiri kapena mpaka mainchesi 4 ku chitoliro choyendetsera chitoliro. Mitundu iyi ya ma flange ndi yabwino kuposa kuphatikiza ma butt-weld reducers ndi ma standard flanges chifukwa ndi otsika mtengo komanso opepuka. Chimodzi mwa zipangizo zomwe zimagwiritsidwa ntchito kwambiri pa ma expansion flanges ndi A105 ndi chitsulo chosapanga dzimbiri ASTM A182.

Ma flange okulitsa amapezeka mu ma pressure ratings ndi kukula kwake motsatira ANSI kapena ASME B16.5 specifications, omwe amapezeka makamaka convex kapena flat (RF kapena FF). Ma flange ochepetsa, omwe amadziwikanso kuti reducing flanges, amagwira ntchito yosiyana kwambiri poyerekeza ndi ma flange okulitsa, zomwe zikutanthauza kuti amagwiritsidwa ntchito kuchepetsa kukula kwa chitoliro. M'mimba mwake wa chitoliro chothamanga ukhoza kuchepetsedwa mosavuta, koma osati ndi kukula kopitilira 1 kapena 2. Ngati kuyesa kupangidwa kuti kuchepetse kupitirira izi, yankho lozikidwa pa kuphatikiza kwa ma reducers olumikizidwa ndi matako ndi ma flanges okhazikika liyenera kugwiritsidwa ntchito.

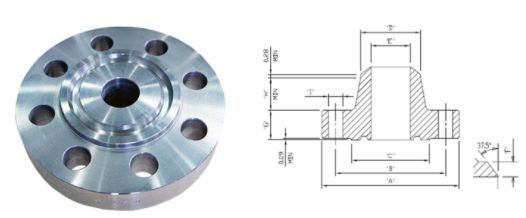

Kukula kwa Flange ndi Zomwe Ziyenera Kuganiziridwa

Kuwonjezera pa kapangidwe ka ntchito ka flange, kukula kwake ndi chinthu chomwe chingapangitse kuti flange isankhidwe kwambiri popanga, kukonza ndikusintha makina a mapaipi. M'malo mwake, kuyenera kuganiziridwanso momwe flange imagwirizanirana ndi chitoliro ndi ma gasket omwe amagwiritsidwa ntchito kuti atsimikizire kukula koyenera. Kuphatikiza pa izi, zinthu zina zomwe zimaganiziridwa ndi izi:

- Dayamita yakunja: Dayamita yakunja ndi mtunda pakati pa m'mphepete ziwiri zosiyana za nkhope ya flange.

- Kukhuthala: Kukhuthala kumayesedwa kuchokera kunja kwa mkombero.

- Chidutswa cha Bolt Circle: Uwu ndi mtunda pakati pa mabowo a bolt omwe amayesedwa kuchokera pakati kupita pakati.

- Kukula kwa chitoliro: Kukula kwa chitoliro ndi kukula kofanana ndi flange.

- Bore Yodziwika: Bore yodziwika ndi kukula kwa m'mimba mwake mkati mwa cholumikizira cha flange.

Kugawa Flange ndi Mulingo wa Utumiki

Ma flanges amagawidwa makamaka ndi kuthekera kwawo kupirira kutentha ndi kupsinjika kosiyanasiyana. Amawonetsedwa pogwiritsa ntchito zilembo kapena ma suffix "#", "lb" kapena "class". Izi ndi ma suffix osinthika ndipo amasiyananso malinga ndi dera kapena wogulitsa. Magulu odziwika bwino alembedwa pansipa:

- 150#

- 300#

- 600#

- 900#

- 1500#

- 2500#

Kupanikizika komweko ndi kulekerera kutentha kumasiyana malinga ndi zinthu zomwe zagwiritsidwa ntchito, kapangidwe ka flange ndi kukula kwa flange. Komabe, chinthu chokhacho chomwe chimasintha ndi kuchuluka kwa kuthamanga kwa mpweya, komwe kumachepa pamene kutentha kukukwera.

Mtundu wa Nkhope ya Flange

Mtundu wa nkhope ndi chinthu chofunikira kwambiri chomwe chimakhudza kwambiri magwiridwe antchito omaliza komanso moyo wa ntchito ya flange. Chifukwa chake, mitundu ina yofunika kwambiri ya nkhope za flange ikusanthulidwa pansipa:

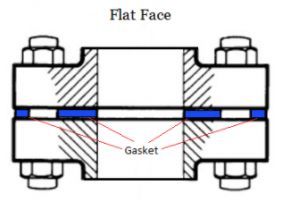

1. Flat Flange (FF)

Pamwamba pa gasket ya flat flange pali malo omwewo ndi pamwamba pa chimango cholumikizidwa. Zinthu zomwe zimagwiritsa ntchito flat flanges nthawi zambiri zimakhala zomwe zimapangidwa ndi nkhungu kuti zigwirizane ndi flange kapena chivundikiro cha flange. Flanges siziyenera kuyikidwa pa inverted side flanges. ASME B31.1 imati polumikiza flat cast iron flanges ku carbon steel flanges, nkhope yokwezedwa pa carbon steel flanges iyenera kuchotsedwa ndipo pamafunika full face gasket. Izi ndi kuletsa kuti franges zazing'ono, zofooka, zosweka zachitsulo kuti zisalowe mu malo opanda kanthu omwe amapangidwa ndi mphuno yokwezedwa ya carbon steel flange.

Mtundu uwu wa nkhope ya flange umagwiritsidwa ntchito popanga zida ndi ma valve pazinthu zonse zomwe chitsulo chopangidwa chimapangidwa. Chitsulo chopangidwa chimakhala chofewa kwambiri ndipo nthawi zambiri chimagwiritsidwa ntchito pokhapokha kutentha kochepa komanso kuthamanga pang'ono. Nkhope yathyathyathya imalola ma flange onse awiri kukhudzana kwathunthu pamwamba ponse. Flat Flanges (FF) ili ndi malo olumikizirana omwe ali kutalika kofanana ndi ulusi wa bolt wa flange. Zotsukira nkhope zonse zimagwiritsidwa ntchito pakati pa ma flange awiri athyathyathya ndipo nthawi zambiri zimakhala zofewa. Malinga ndi ASME B31.3, ma flange athyathyathya sayenera kulumikizidwa ndi ma flange okwera chifukwa cha kuthekera kotulutsa madzi kuchokera ku cholumikizira chopangidwacho.

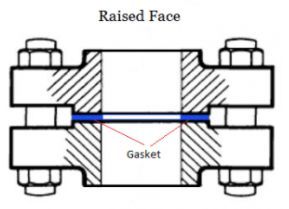

2. Flange Yokwezedwa (RF)

Mtundu wa flange wokwezedwa ndi womwe umagwiritsidwa ntchito kwambiri popanga zinthu ndipo umazindikirika mosavuta. Umatchedwa convex chifukwa nkhope ya gasket ili pamwamba pa nkhope ya mphete ya bolt. Mtundu uliwonse wa nkhope umafuna kugwiritsa ntchito mitundu ingapo ya ma gasket, kuphatikizapo mitundu yosiyanasiyana ya ma ring tape ndi zinthu zopangidwa ndi zitsulo monga mawonekedwe ozungulira ndi opindika kawiri.

Ma RF flanges apangidwa kuti aziwonjezera kupanikizika pamalo ang'onoang'ono a gasket, motero akuwongolera kulamulira kwa kuthamanga kwa cholumikizira. Ma diameter ndi kutalika malinga ndi mulingo wa kuthamanga ndi m'mimba mwake zafotokozedwa mu ASME B16.5. Mulingo wa kuthamanga kwa flange umatchula kutalika kwa nkhope yomwe ikukwezedwa. Ma RF flanges cholinga chake ndi kuwonjezera kukakamiza pamalo ang'onoang'ono a gasket, motero kuwonjezera mphamvu yowongolera kuthamanga kwa cholumikizira. Ma diameter ndi kutalika malinga ndi kalasi ya kuthamanga ndi m'mimba mwake zafotokozedwa mu ASME B16.5. Ma rating a pressure flange.

3. Mphete ya mphete (RTJ)

Ngati chisindikizo chachitsulo ndi chitsulo chikufunika pakati pa ma flange ogwirizana (chomwe ndi chofunikira kuti pakhale kupanikizika kwakukulu ndi kutentha kwambiri, mwachitsanzo, pamwamba pa 700/800 C°), Ring Joint Flange (RTJ) imagwiritsidwa ntchito.

Mphete yolumikizira mphete ili ndi mpata wozungulira womwe umalola gasket yolumikizira mphete (yozungulira kapena yamakona anayi).

Pamene ma ring joint flanges awiri alumikizidwa pamodzi kenako n’kumangidwa, mphamvu ya bolt yomwe imagwiritsidwa ntchito imasokoneza gasket yomwe ili mumzere wa flange, zomwe zimapangitsa kuti chisindikizo cholimba kwambiri chachitsulo ndi chitsulo chikhale cholimba. Kuti izi zitheke, zinthu za gasket ya ring joint ziyenera kukhala zofewa (zofewa kwambiri) kuposa zinthu za ma flanges.

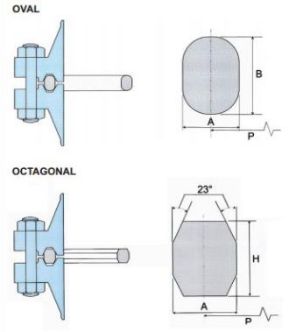

Ma flange a RTJ amatha kutsekedwa ndi ma gasket a RTJ amitundu yosiyanasiyana (R, RX, BX) ndi ma profiles (monga octagonal/elliptical a mtundu wa R).

Gasket yodziwika bwino ya RTJ ndi mtundu wa R wokhala ndi gawo la octagonal cross-section, chifukwa imatsimikizira kuti pali chisindikizo champhamvu kwambiri (gawo la oval cross-section ndiye mtundu wakale). Komabe, kapangidwe ka "flat groove" kamalandira mitundu yonse iwiri ya magasket a RTJ okhala ndi gawo la octagonal kapena oval cross-section.

4. Ma flange a lilime ndi groove (T & G)

Ma flange awiri a lilime ndi groove (nkhope za T & G) zimagwirizana bwino: flange imodzi ili ndi mphete yokwezedwa ndipo inayo ili ndi groove komwe imalowa mosavuta (lilime limalowa mu groove ndikutseka cholumikizira).

Ma flange a lilime ndi groove amapezeka m'makulidwe akuluakulu ndi ang'onoang'ono.

5. Ma Flanges Aamuna ndi Akazi (M & F)

Mofanana ndi ma flange a lilime ndi mipata, ma flange a amuna ndi akazi (mtundu wa nkhope ya M & F) amagwirizana.

Flange imodzi ili ndi malo omwe amapitilira malo ake, flange yachimuna, ndipo flange inayo ili ndi malo ofanana omwe amapangidwa pamwamba pake, flange yachikazi.

Flange pamwamba pa mapeto

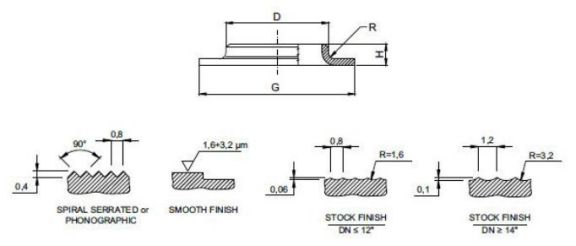

Pofuna kuonetsetsa kuti flange ikugwirizana bwino ndi gasket ndi flange yolumikizirana, malo a flange amafunika kukhwima pang'ono (kumaliza kwa RF ndi FF flange kokha). Mtundu wa kukhwima kwa nkhope ya flange umatanthauza mtundu wa "kumaliza kwa flange".

Mitundu yodziwika bwino ndi ya stock, concentric serrated, spiral serrated ndi yosalala flange faces.

Pali zomaliza zinayi zazikulu za flanges zachitsulo, komabe, cholinga chofanana cha mtundu uliwonse wa flanges ndi kupanga kukhwima komwe kumafunidwa pamwamba pa flanges kuti zitsimikizire kuti flange, gasket ndi flange yolumikizana zikugwirizana bwino kuti zipereke chisindikizo chabwino.

Nthawi yotumizira: Okutobala-08-2023